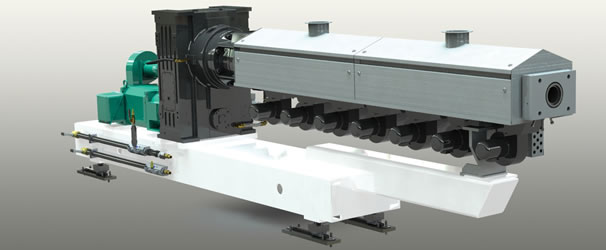

Compact CHP extruder

Davis-Standard has introduced a new compact extruder engineered for extrusion coating applications. The CHP's design offers a smaller footprint and lighter weight to allow for easier addition to an existing carriage or platform structure. This provides processors with a space-saving replacement or co-extrusion addition for increasing output and line speed.

This design addresses profitability factors such as reduced raw material loss, improved outputs and greater application development,

The CHP is built for exceptional performance with improved transition times and significantly higher processing rates than conventional extruders. We're excited about the results we'll see in the field.

The CHP is available in sizes ranging from 52 to 100mm, providing efficient mixing that delivers low pressure and melt temperature variability, and output rates claimed to be up to 80 to 100 percent higher than current extruder options.

The reduced residence time of 3:1 with a faster purge between resins and colors supports quick changeovers, minimizing raw material loss. Davis-Standard has a CHP extruder at its laboratory facility in Pawcatuck, Connecticut, for customers to run trials and validate processing opportunities prior to purchase.